Project 3: Pulse-Width Modulation and Proportional-Derivative Control

- Project checkpoint is due by Thursday, April 5th at 5:00pm.

- All components of the project are due by Thursday, April 12th

at 5:00pm.

- Discussion within groups is fine.

- Discussion across groups may not be about the specifics of the

solution (general programming/circuit issues are fine to

discuss).

Project Goals

At the end of this project, you should be able to:

- control the speed and direction of DC motors through an H-bridge circuit,

- implement and tune a proportional-derivative control law that

maintains the hovercraft's heading at some desired orientation, and

- implement a high-level control law that decides when to brake

and when to use the PD control law.

Project Components

All components are required to receive full credit for the project.

Part 1: Microcontroller Circuit

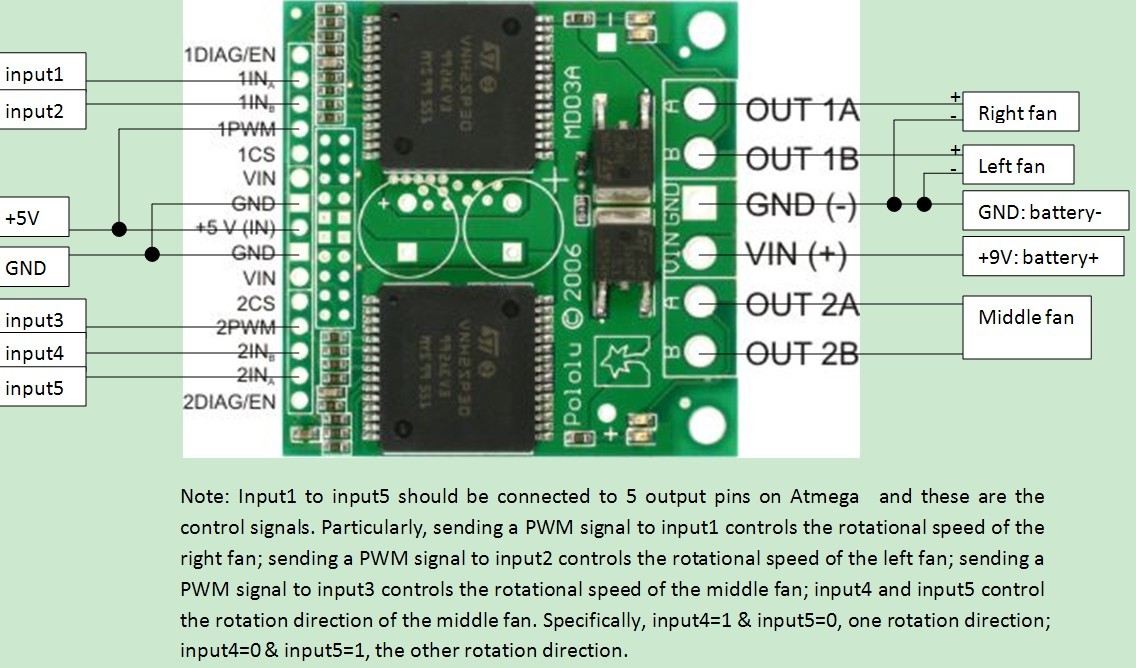

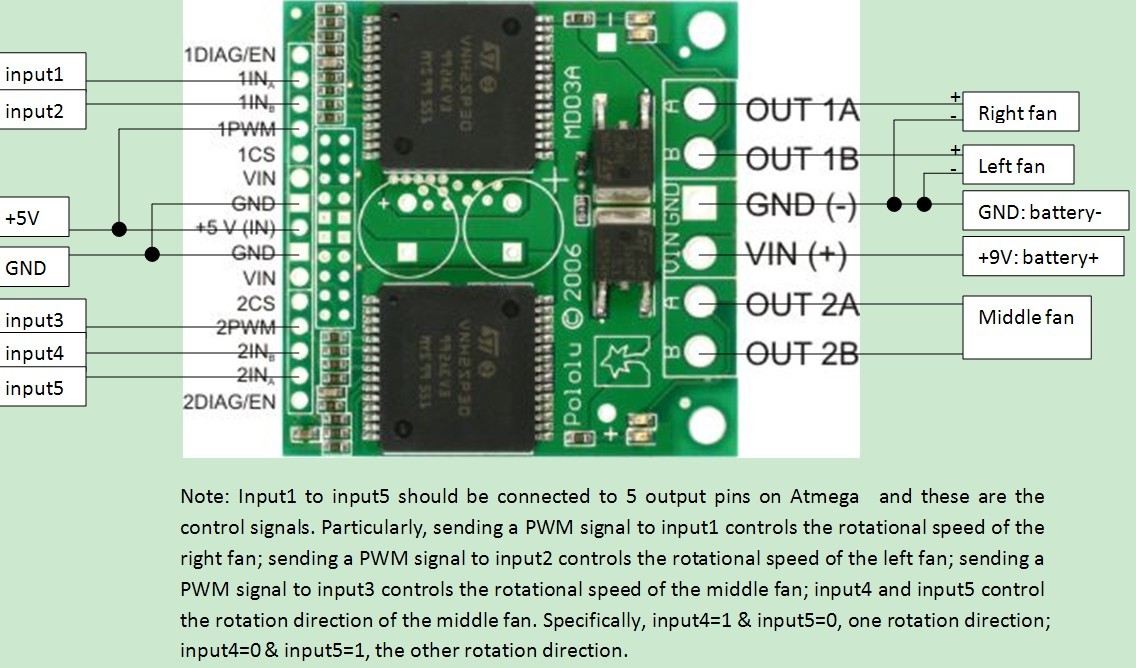

The current amplifier board is composed of two full H-Bridge

circuits. We will be using one full H-Bridge to control the middle

fan (allowing us to control rotation speed and direction). We will

split the other H-Bridge into two "Half Bridges": one for each of the

left and right fans. This will allow us to control speed of these two

fans, but not direction.

The detailed documentation for the motor control board can be found on the

Lab

Hardware page: see the Motor Control Board section. The

high-level view is given below.

Add wires to connect the motor control board to the fans and to the batteries:

- Connect GND and VIN directly to the battery (not to your

5V regulated power supply!!!)

- Connect the middle fan to port 2 (OUT 2A and 2B)

- Connect the right fan: red wire to OUT 1A and black wire to GND

- Connect the left fan: red wire to OUT 1B and black wire to GND

Connect the current amplifier board to your Atmel chip (the 15 pin

connector on the left side of the board in the picture below):

- Connect 1PWM and +5V(IN) to your Atmel's +5V power supply

- Connect GND and GND to your Atmel's ground

- Choose one of: timer1, 3, 4 or 5. For the chosen timer, you must have

all three PWM pins available (they are labeled OCXA, OCXB and

OCXC on the Arduino circuit, where X = 1, 3, 4 or 5).

- Connect the following to your Atmel (do NOT use B0 ... B3):

- 1INA: Pulse-Width Modulated (PWM) input for the right

fan. Connect to OCXA

- 1INB: PWM input for the left fan. Connect to OCXB

- 2PWM: PWM input for the middle fan. Connect to OCXC

- 2INB/2INA: direction control for the middle fan (0/1:

one direction; 1/0: the other direction). Connect to

free digital output pins.

Part 2: Fan Control Interface

Note: this part will count for a total of one personal

programming credit

Create the function interface that will generate the PWM signals

for each of the three PWM inputs to the motor control board.

Define two new variable types in "project.h":

typedef enum {

BRAKE,

HOVER

} MotorDirection;

typedef enum {

LEFT = 0,

RIGHT = 1

}SensorSide;

MotorDirection and SensorSide are the variable types. BRAKE and HOVER

are the two values that MotorDirection variables can take on. LEFT and

RIGHT are the two values that SensorSide variables can take on.

Remember to include "project.h" in your C file.

Implement the following functions:

-

void set_middle_direction(MotorDirection direction) that sets the

direction bits for the middle fan.

If direction == HOVER, then the craft should hover (assuming an

appropriate level of thrust).

If direction == BRAKE, then the craft should be pulled to the ground.

- void set_middle_magnitude(int16_t magnitude) that sets

the thrust magnitude for the middle fan. This function must

ensure that magnitude falls within the range of 0... 1023

(which correspond to 0% ... 100% duty cycle). If it does not,

then the value should be clipped to this range.

- void set_lateral_magnitudes(int16_t magnitude_left, int16_t

magnitude_right) that sets the thrust magnitude for the left

and right fans. This function must

ensure that magnitude_left and magnitude_right fall

within the range of 0... 1023 (which correspond to 0% ... 100%

duty cycle). If either does not, then the offending value

should be clipped to this range.

Note:

- Initialization of the three PWM channels must happen within

your main() function (see the lecture notes on timers).

Testing

Implement the following functions:

Modify your main function such that it executes one of the two

above functions, depending on the initial state of switch 0.

Part 3: Proportional Derivative Control

Note: this part will count for one personal programming credit

Create a function that will implement a proportional-derivative

controller:

void pd_control(int16_t error, int16_t rotation_rate, uint16_t forward_thrust)

Where:

- error is the heading error,

- rotation_rate is the rate of craft rotation, and

- forward_thrust is the total forward thrust is the sum of the left/right thrust magnitudes (this

latter value will be between 0 ... 1023).

This function will:

- compute a left/right differential control signal for the fans

using the proportional-derivative control law. This control

law must include the heading error and current rotation rate.

Within this function, heading error must take into account a small

dead-band around zero error and maximum error values (a good place to start is: dead-band +/- 5 degrees; and max error +/- 45 degrees).

- add this differential control signal to the forward_thrust

input.

- set magnitude_left and magnitude_right.

Note: remember that integer math is much more efficient. However, you

have to be more careful about your data types and the order of your

multiplication and division operations.

Notes on tuning the PD control parameters:

- Start with Kp = 0, and slowly bring Kv up to a reasonable

level. Your craft should resist rotation. If it accelerates

instead, then you probably have the sign of Kv wrong.

- Next, set Kv = 0, and slowly bring Kp up to a reasonable

level. You will see oscillations (this is ok for the

instant). If the craft turns away from the goal, they you have the sign

wrong on Kp.

- Now use your selected Kp and Kv. When you have oscillations,

your choices are to: increase Kv or reduce Kp. Make adjustments slowly.

- There is such a thing as Kp being too high. This comes from the

fact that from one control decision to the next there is some

amount of delay. The larger the delay, the larger the

oscillations. In this case, your only choice is to drop Kp

(and likely Kv, too).

Part 4: High-Level Control

Note: this part will count for one personal programming credit

For this part, you will implement a high-level control loop that will

cycle once every 50 ms. For each of these control steps, if

no obstacles are visible, the craft will hover and move forward. If

an obstacle is detected, then the craft should brake.

-

Modify the your program so that it is structured as follows

(you will, of course, need to add other code):

// Global flag

volatile uint8_t flag_timing = 0;

// Interrupt service routine: called every time

// the timer 0 counter transitions from 0xFF to 0.

// Period of flag_timing is 3 * 256 * 1024 / 16000000 = 49.152 ms

ISR(TIMER0_OVF_vect) {

static uint8_t count = 0; // Set to zero at beginning of program only

if(++count == 3){

// Set the flag to indicate that the period has passed

flag_timing = 1;

count = 0;

}

};

int main(void) {

int16_t counter = 0;

int16_t heading, heading_last, heading_goal, heading_error;

int16_t rotation_rate, distance_left, distance_right;

#APPROPRIATE VARIABLE DECLARATIONS HERE#

#APPROPRIATE INITIALIZATIONS HERE#

timer0_config(TIMER0_PRE_1024); // Prescale by 1024

timer0_enable(); // Enable the timer 0 overflow interrupt

sei(); // Enable global interrupts

// Initialize variables

heading_goal = get_heading();

distance_left = get_ir_distance(LEFT);

distance_right = get_ir_distance(RIGHT);

// Begin to lift off the ground

set_middle_direction(HOVER);

#RAMP UP MIDDLE THRUST TO HOVER#

// Loop for ~30 seconds

while(counter < 20*30) {

heading = get_heading();

heading_error = compute_heading_error(heading, heading_goal);

rotation_rate = get_rotation_rate();

distance_left = get_ir_distance(LEFT);

distance_right = get_ir_distance(RIGHT);

// Display

#APPROPRIATE CODE FOR DISPLAYING SENSOR STATES WITH YOUR LEDS#

// Obstacles?

if(#obstacles#) {

#BRAKE#

}else{

// No obstacles: steer to desired heading

pd_control(heading_error, rotation_rate, #PICK AN APPROPRIATE VALUE#);

}

// Increment time

++counter;

if(flag_timing) {

// Error condition: your code body is taking too much

// time.

#Indicate this with an LED display of some form#

}

// Wait for the flag to be set (happens once every ~50 ms)

while(flag_timing == 0) {};

// Clear the flag for next time.

flag_timing = 0;

}

#RAMP DOWN MIDDLE THRUST TO ZERO#

while(1){}; // Spin forever

}

Part 5: Hovercraft Layout

Revisit the mounting of your components on the Frisbees:

- Make sure that all components and cables are secure and that no

wires are near the fans.

- Make sure that the compass is far away from the motors and any

wires that carry a substantial amount of current

- Check that the Frisbee is balanced (i.e., the center of mass is

at the center of the Frisbee)

Let us know if you need any additional components for mounting.

References

What to Hand In

The project checkpoint is due by Thursday, April 5th at 5:00pm.

- By this time, you should have parts 1-3 complete or near

completion (including testing).

- Code: check in your documented code to the subversion

repository by the deadline.

- Code review/demonstration: meet with the instructor or the TA to

discuss your current implementation and to show what you have

working. Plan on a 30 minute meeting. All group members should

be present.

All components of the project are due by Thursday, April 12th at 5:00pm.

Grading

Group grade distribution:

- 10%: Project checkpoint

- 30%: Project implementation

- 30%: Demonstration/presentation of working project (to either

of the TA or the instructor)

- 30%: Code documentation and group report

Grades for individuals will be based on the group grade, but weighted

by the assessed contributions of the group members.

fagg [[at]] cs.ou.edu

Last modified: Wed Apr 11 22:41:46 2012